|

MICRODISC ELECTRODE

ARRAYSTM

(MDEAs) |

|

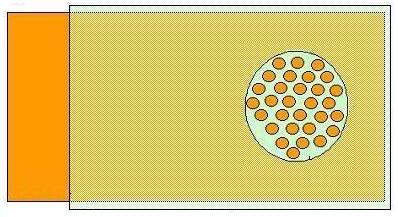

MDEA DEVICES |

Number of Discs |

Disc dimensions |

Active Area |

Conductor |

|

MDEA 360 |

1 disc |

3,600 microns diameter discs |

0.10 cm2 |

Au, Pt, ITO |

|

MDEA 250 |

207 microdiscs |

250 microns diameter discs |

0.10 cm2 |

Au, Pt, ITO |

|

MDEA 100 |

1,296 microdiscs |

100 microns diameter discs |

0.10 cm2 |

Au, Pt, ITO |

|

MDEA 050 |

5,184 microdiscs |

50 microns diameter discs |

0.10 cm2 |

Au, Pt, ITO |

|

|

|

|

|

|

MDEA Brochure (PDF) |

|||||

|

|||||||||

|

Ø Chip Substrate: |

Schott D263 Borosilicate Glass |

|

|||||||

|

|

Dielectric Constant, Epsilon(r) at 1 MHz |

6.7 |

|||||||

|

|

Dielectric Loss Angle, tan delta, at 1 MHz |

61 x 10-4 |

|||||||

|

|

Electrical Resistivity (50 Hz) (250 C) |

1.6 x 10^8 ohm cm |

|||||||

|

|

Coefficient of Linear Thermal Expansion, * 20-300 Deg C |

7.2 x 10^-6 K^-1 |

|||||||

|

|

Refractive Index at 20 C, ne ( Lambda = 546.1 nm) |

1.5249 |

|||||||

|

|

|

|

|||||||

|

Ø Metallization: |

100 Å Ti|W / 1000 Å Au or Pt and ITO = 10 Ohms/sq |

|

|||||||

|

|

|

|

|||||||

|

Ø Insulating Top Layer: |

Silicon Nitride (Si3N4) |

|

|||||||

|

|

|

|

|||||||

|

|

|

No of Discs |

Electroactive Area (cm2) |

Geometric Area (cm2) |

|||||

|

Ø MDEA 360 |

A single disc, 3.60 mm in diameter. |

1 |

1.0 x10-1 |

1.0 x10-1 |

|||||

|

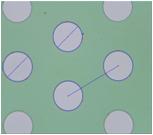

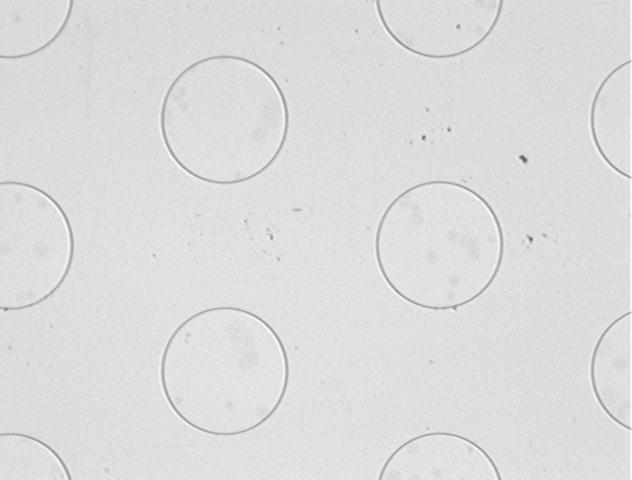

Ø MDEA 250 |

207 separate discs, each 250 mm in diameter and arranged 500 mm on centers in a hexagonal close packaed array. |

207 |

1.0 x10-1 |

4.5 x10-1 |

|||||

|

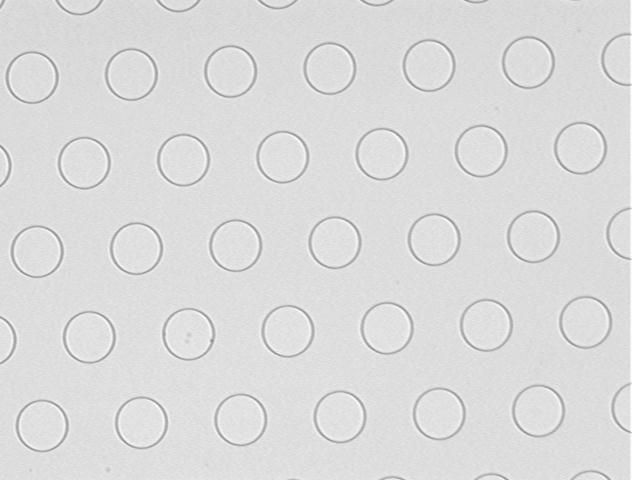

Ø MDEA 100 |

1,296 separate discs, each 100 mm in diameter and arranged 200 mm on centers in a hexagonal close packaed array. |

1,296 |

1.0 x10-1 |

4.5 x10-1 |

|||||

|

Ø MDEA 050 |

5,184 separate discs, each 50 mm in diameter and arranged 100 mm on centers in a hexagonal close packaed array. |

5,184 |

1.0 x10-1 |

4.5 x10-1 |

|||||

|

|

|

|

|

|

|||||

|

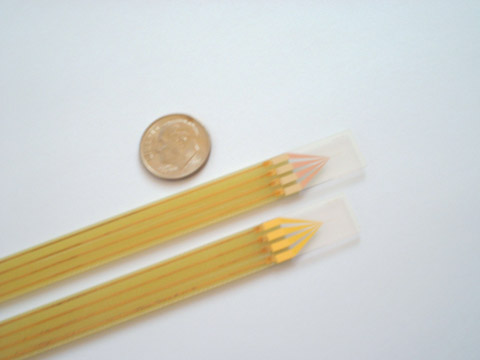

Ø MDEA Chip Dimensions |

Un-packaged Die |

Packaged Die |

|||||||

|

|

(l x w x t) |

(l x w x t) |

|||||||

|

MDEA XXX |

2.00 x 1.00 x 0.05 cm |

13.2 x 1.38 x 0.7 cm |

|||||||

|

|

|

|

|||||||

|

Ø Packaging |

|

|

|||||||

|

Electrode Body: |

PVC-Jacketed printed circuit board |

||||||||

|

Encapsulant: |

Epoxy header. Polyimide packaged chip. |

||||||||

|

Leadwires: |

Color coded, 28 AWG stranded copper, shielded, and PVC jacketed |

||||||||

Back to Index |

|||||||||